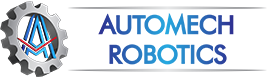

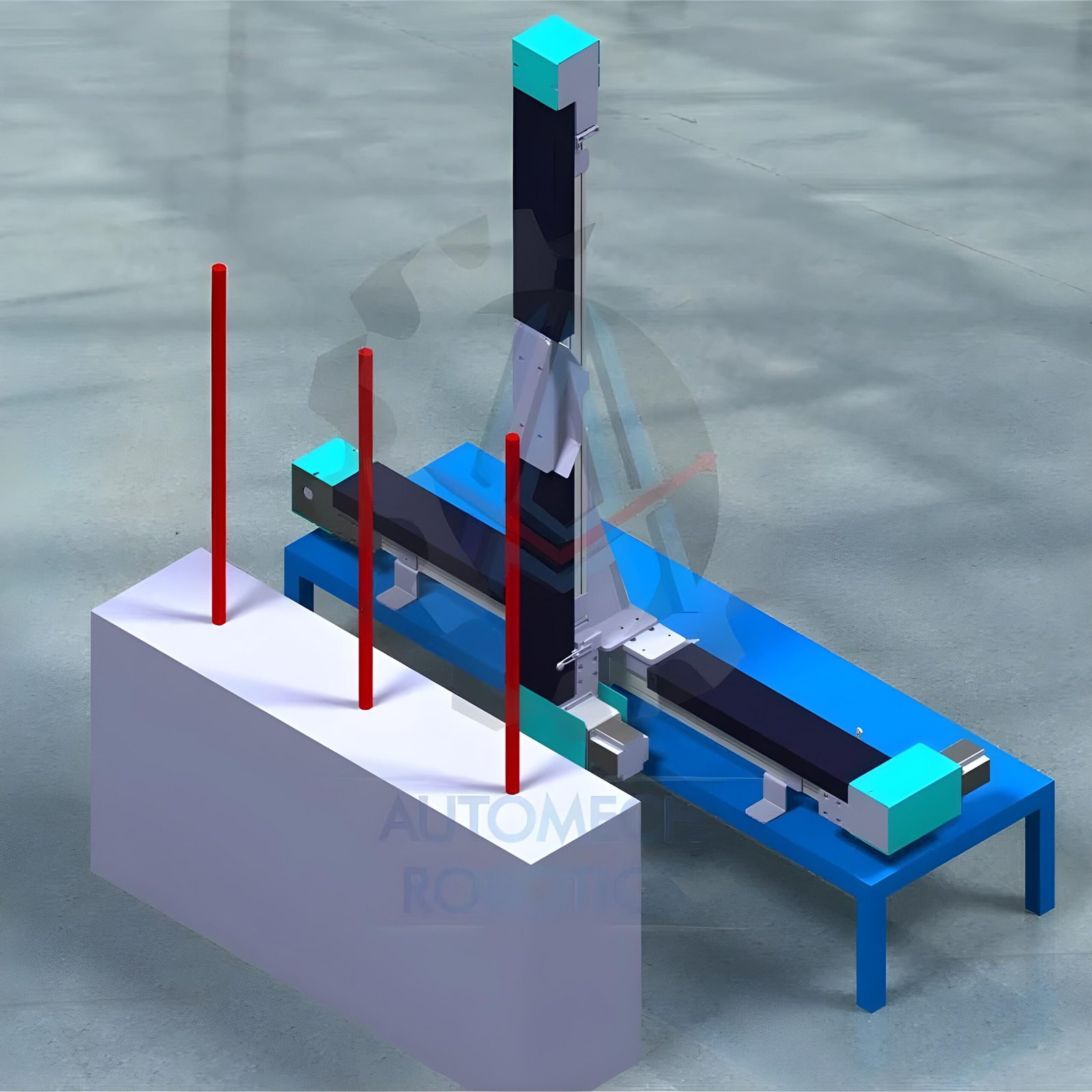

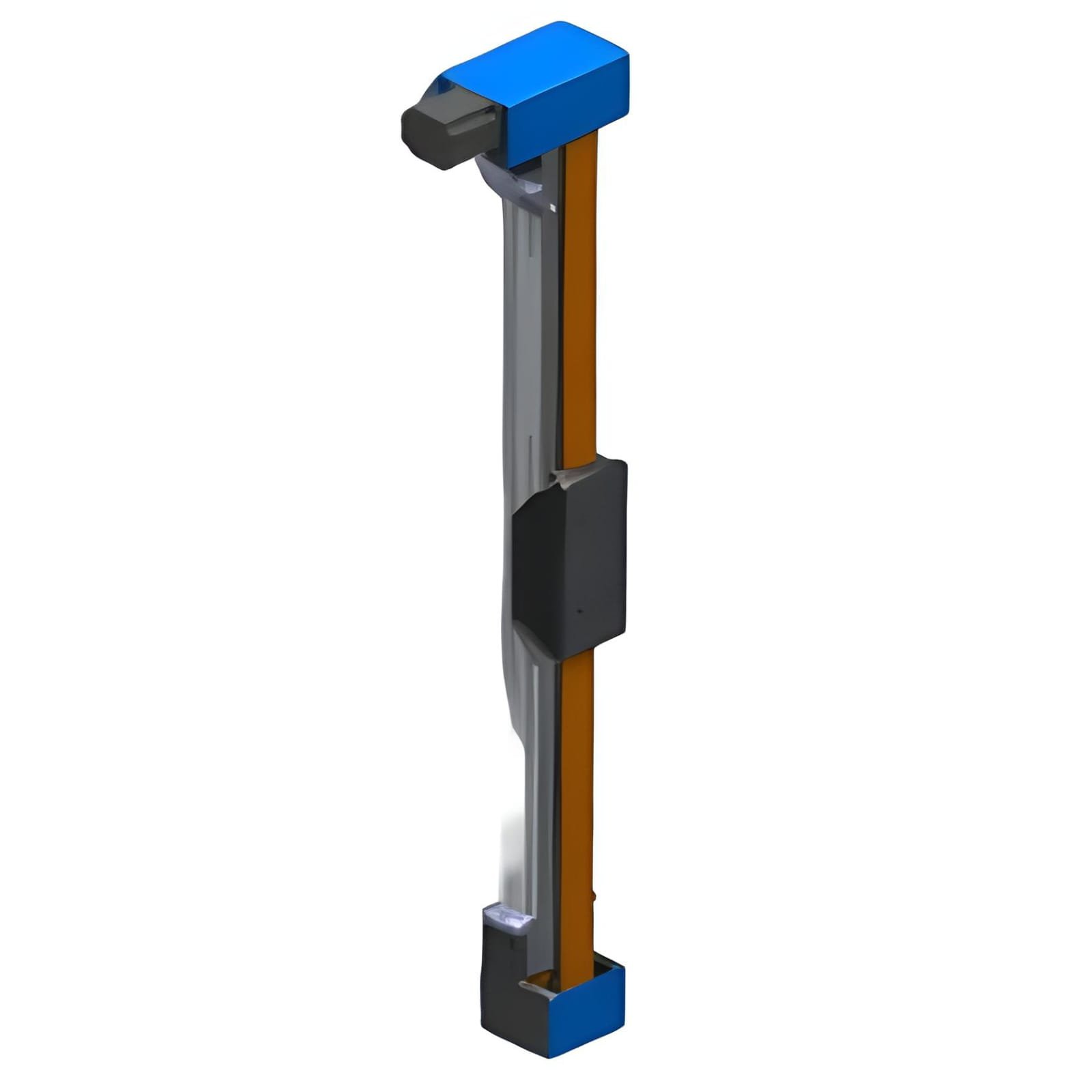

Our custom-designed reciprocators linear slide manipulator is tailored for a wide range of robotic applications, offering versatility and precision.

Types:

- Reciprocators: These devices facilitate back-and-forth motion in a linear path, ideal for tasks requiring repetitive actions such as painting, welding, or assembly.

- Linear Slide: Our linear slide systems provide smooth and accurate linear motion, essential for precise positioning in various industrial processes.

- Manipulator: With our manipulator solutions, users can achieve intricate movements and manipulations, empowering robots to handle complex tasks with ease.

Applications: Suitable for all robotic applications, our reciprocators linear slide manipulator enhances efficiency and productivity across industries such as manufacturing, automation, and logistics

Types of Linear Slides:

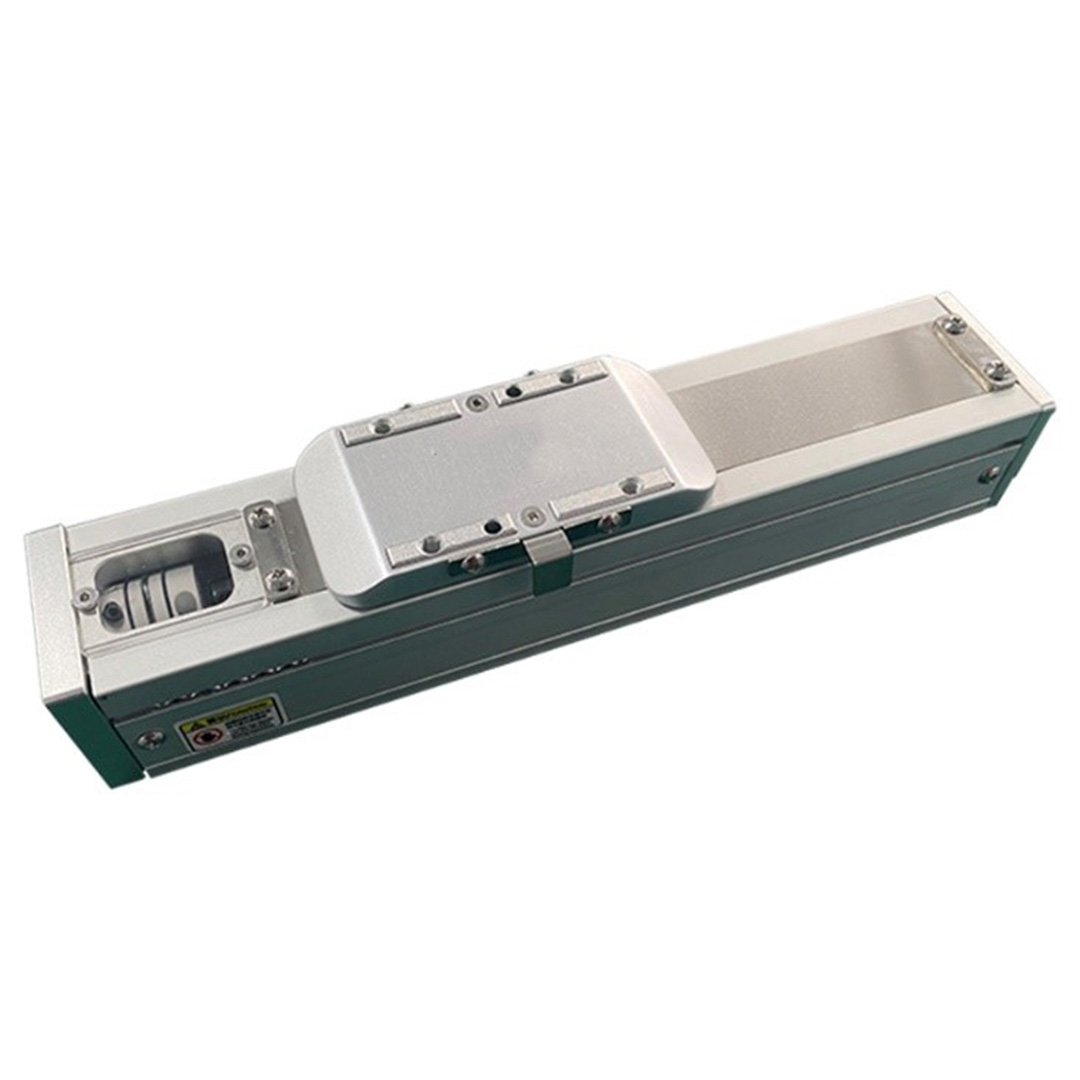

Ball Bearing Linear Slide:

- Smooth and low-friction linear motion facilitated by ball bearings.

- Ideal for applications requiring high precision and repeatability, such as CNC machining and semiconductor manufacturing.

Dovetail Linear Slide:

- Features a dovetail-shaped carriage and rail for high rigidity and stability.

- Suitable for applications with moderate precision requirements, such as woodworking machinery and packaging equipment.

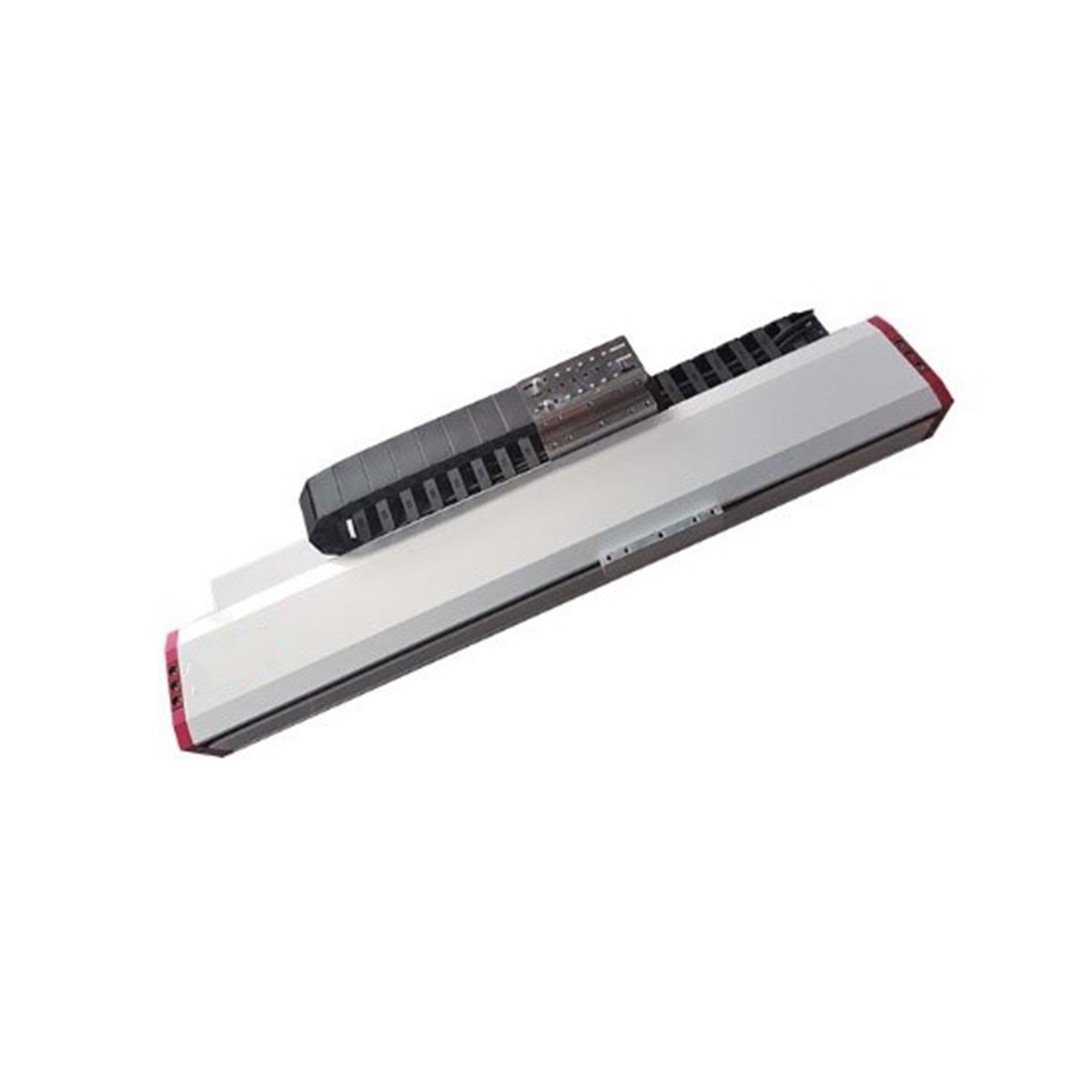

Linear Motor Slide:

- Utilizes linear motors for direct-drive motion without mechanical transmission components.

- Offers high acceleration, velocity, and positioning accuracy, making it suitable for semiconductor inspection and high-speed automation.

Belt-Driven Linear Slide:

- Transmits motion along the linear axis using a belt and pulley system.

- Cost-effective solution for medium to high precision applications like packaging machinery and material handling systems.

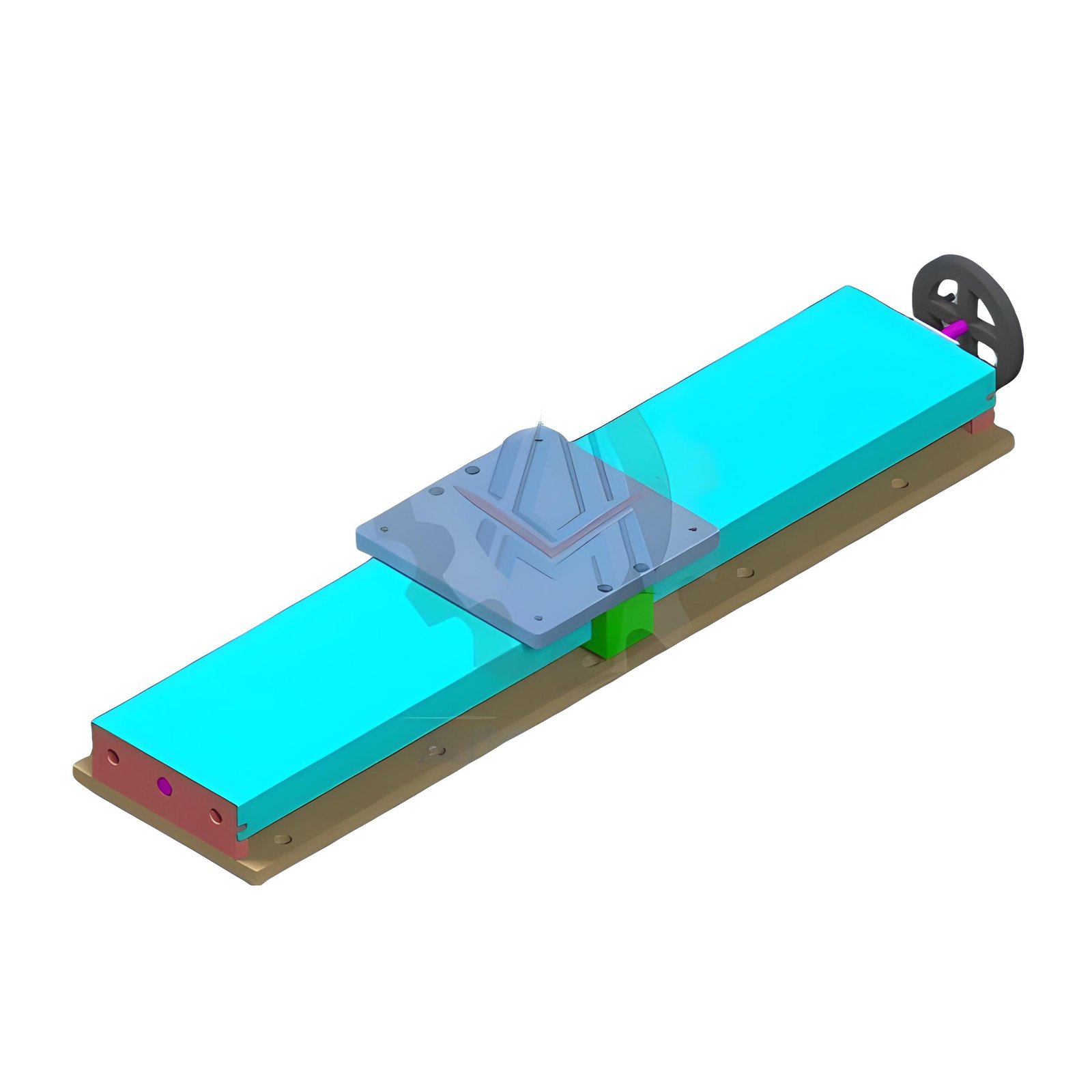

Screw-Driven Linear Slide:

- Converts rotary motion into linear motion using a screw mechanism (e.g., lead screw or ball screw).

- Known for high mechanical efficiency and repeatability, making them suitable for CNC routers and machine tools.

Types of Reciprocators:

Pneumatic Reciprocator:

- Utilizes pneumatic power to drive back-and-forth motion.

- Commonly used in applications such as spray painting and assembly lines.

Electric Reciprocator:

- Driven by electric motors to provide precise and controlled reciprocating motion.

- Ideal for tasks requiring programmable motion profiles and varying speeds, like welding and pick-and-place operations.

Hydraulic Reciprocator:

- Operates using hydraulic power to achieve smooth and powerful reciprocating motion.

- Suitable for heavy-duty applications such as metal forming and forging.

Linear Reciprocating Motion Mechanism:

- Employs mechanical linkages to convert rotary motion into linear reciprocating motion.

- Used in various applications where precise and controlled linear motion is required, such as in pumps and engines.

- Each type of linear slide and reciprocator offers unique advantages and is selected based on factors such as load capacity, speed, precision, and environmental conditions of the application.