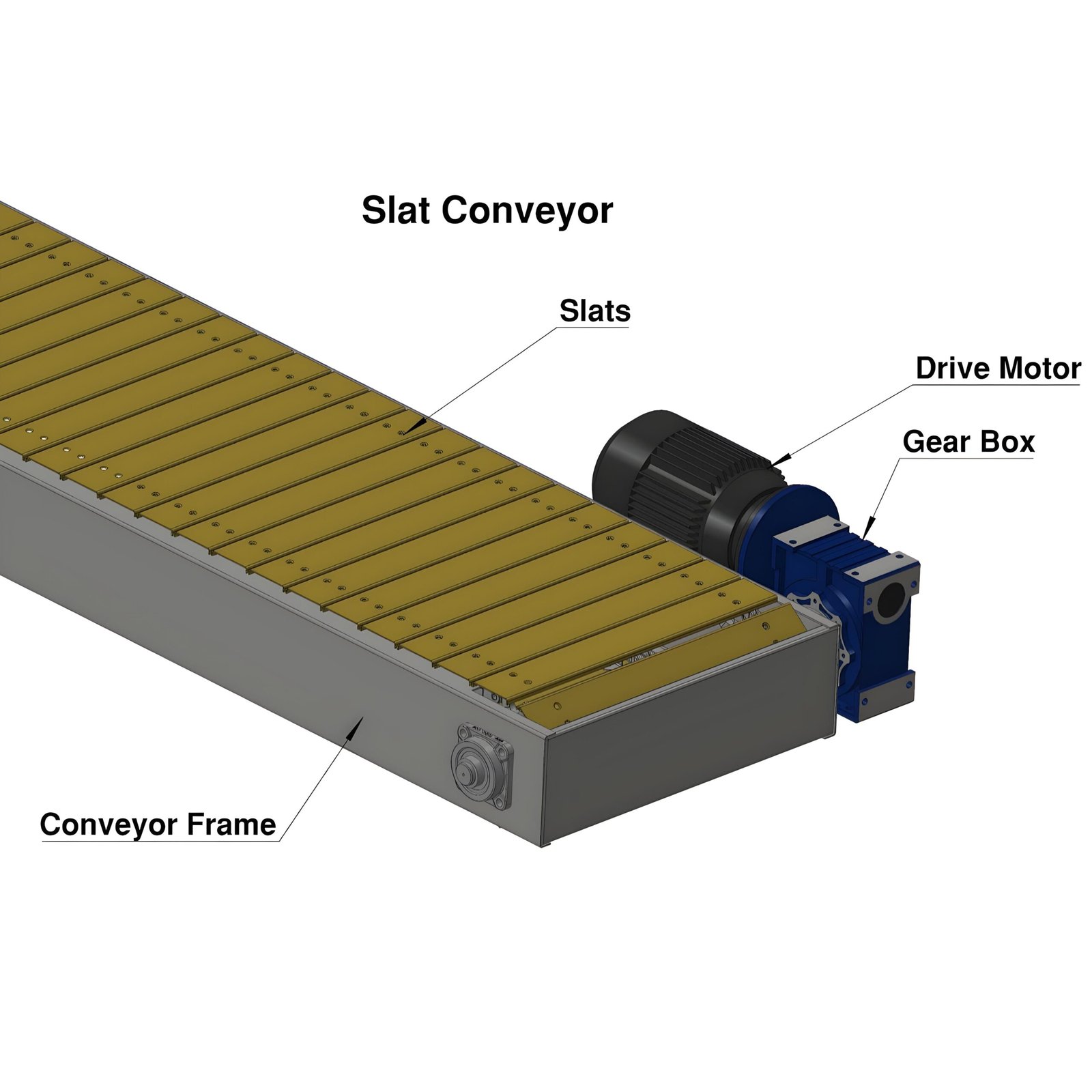

Custom Design and Engineering

- We work closely with you to understand your unique requirements.

- Our team of experienced engineers will design a conveyor system that fits your space, product type, and operational demands.

- 3D modeling and simulations ensure optimal design and functionality before manufacturing.

Manufacturing and Assembly

- State-of-the-art manufacturing facilities equipped with advanced machinery.

- High-quality materials and components ensure durability and longevity.

- Skilled technicians assemble and test each conveyor to guarantee performance and reliability.

Installation and Integration

- Professional installation services to ensure seamless integration with your existing systems.

- Minimization of downtime during the transition process.

- Comprehensive training for your staff to operate and maintain the new conveyor system effectively.

Maintenance and Support

- Preventive maintenance programs to keep your conveyor running smoothly.

- On-site and remote technical support available 24/7.

- Quick response times to minimize disruptions to your operations.

Types of Conveyor Systems

- Belt Conveyors

- Description: Ideal for transporting a wide variety of materials, from lightweight to heavy-duty.

- Applications: Manufacturing, packaging, assembly lines.

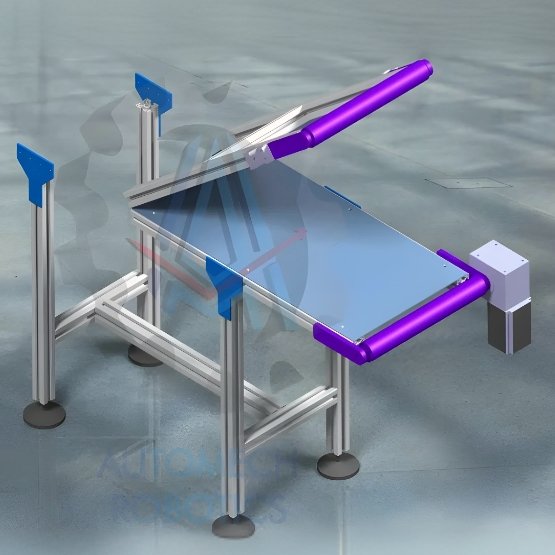

- Roller Conveyors

- Description: Perfect for handling heavier loads and large items, utilizing rollers to move products.

- Applications: Warehousing, distribution centers, heavy manufacturing.

- Chain Conveyors

- Description: Suitable for moving heavy loads and pallets using chains as the primary mode of conveyance.

- Applications: Automotive, heavy machinery, industrial manufacturing.

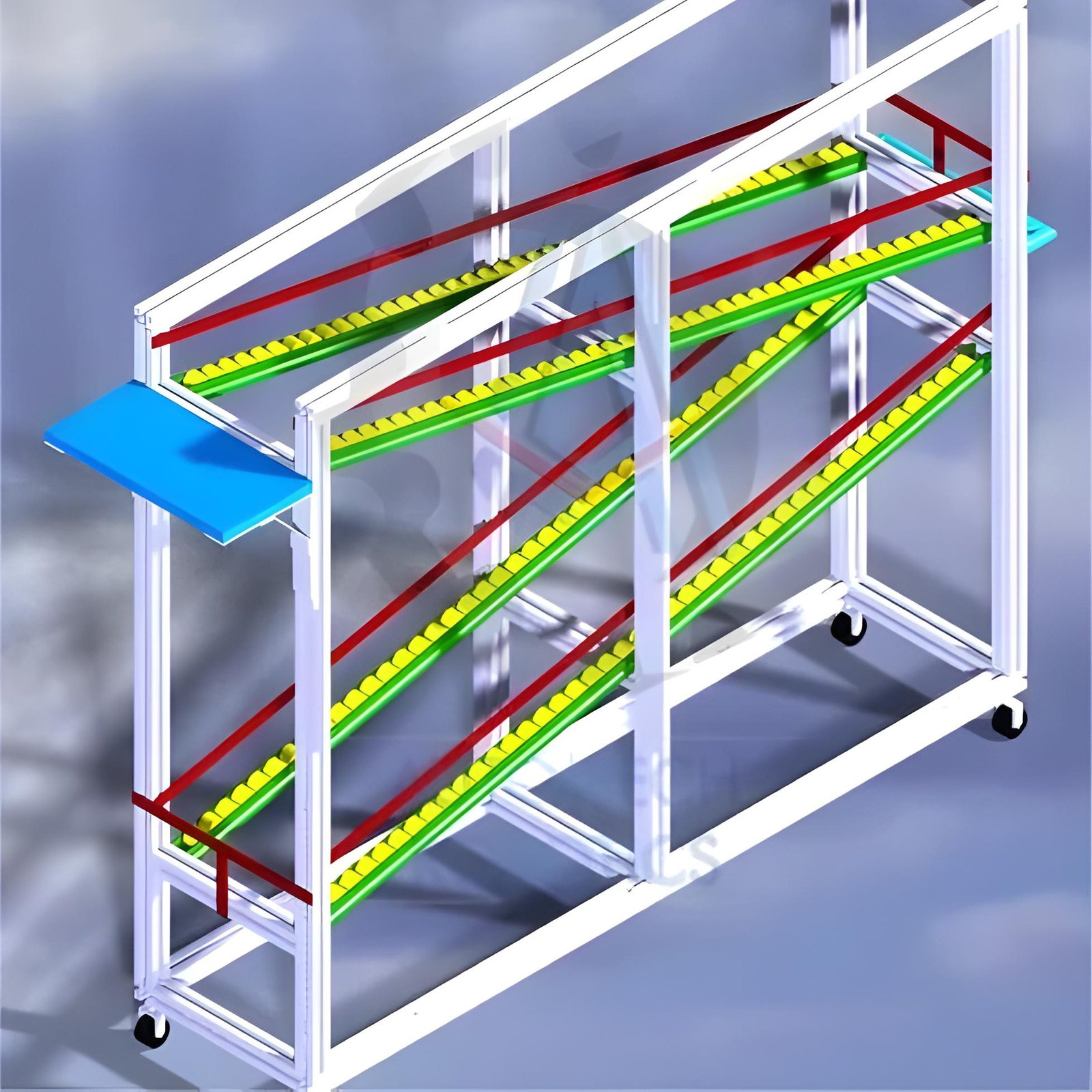

- Slat Conveyors

- Description: Uses slats connected to chains to move products, providing a durable and stable surface.

- Applications: Food and beverage, bottling, and packaging industries.

- Screw Conveyors

- Description: Ideal for moving bulk materials such as grains, powders, and granules using a rotating helical screw blade.

- Applications: Agriculture, food processing, chemical industries.

- Modular Belt Conveyors

- Description: Offers flexibility with modular components, easy to clean and maintain.

- Applications: Food processing, pharmaceuticals, packaging.

- Overhead Conveyors

- Description: Space-saving conveyors that move products along overhead tracks.

- Applications: Automotive assembly lines, paint shops, warehousing.

- Pneumatic Conveyors

- Description: Uses air pressure to move bulk materials through enclosed pipelines.

- Applications: Grain handling, cement industry, food processing.

- Vibrating Conveyors

- Description: Moves products using vibration, ideal for delicate or fragile items.

- Applications: Food processing, recycling, and mining industries.

- Magnetic Conveyors

- Description: Uses magnets to move ferrous materials along a conveyor path.

- Applications: Metal fabrication, recycling, electronics manufacturing.

- Vertical Conveyors

- Description: Transports materials vertically between different levels.

- Applications: Multi-story facilities, warehouses, manufacturing plants.

- Spiral Conveyors

- Description: Efficiently moves products up or down a spiral path, saving floor space.

- Applications: Packaging, warehousing, food and beverage.

Industries We Serve

- Food and Beverage

- Automotive

- Pharmaceutical

- E-commerce and Warehousing

- Manufacturing

- Logistics and Distribution