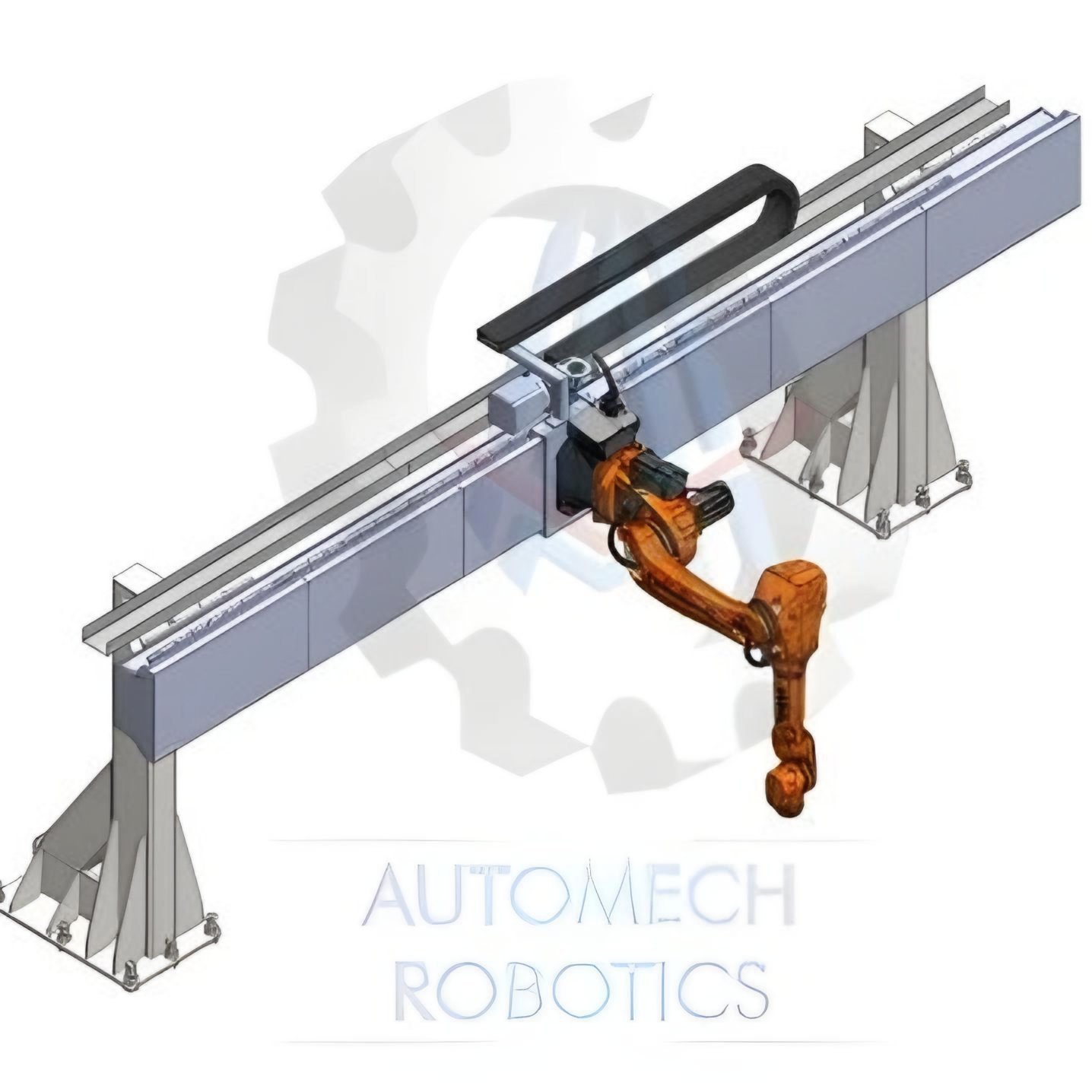

Our Gantry Systems are designed to be customized to meet the specific needs of our clients. Whether you require a system for industrial automation, material handling, or precision positioning, our tailored solutions ensure optimal performance and efficiency.

Types of Gantry Systems

Single Axis Gantry

- Description: Ideal for applications requiring linear movement in a single direction.

- Applications: CNC machines, material handling, pick-and-place operations.

Dual Axis Gantry

- Provides movement along two axes, offering greater flexibility and precision.

- Applications: Automated assembly lines, 3D printing, inspection systems.

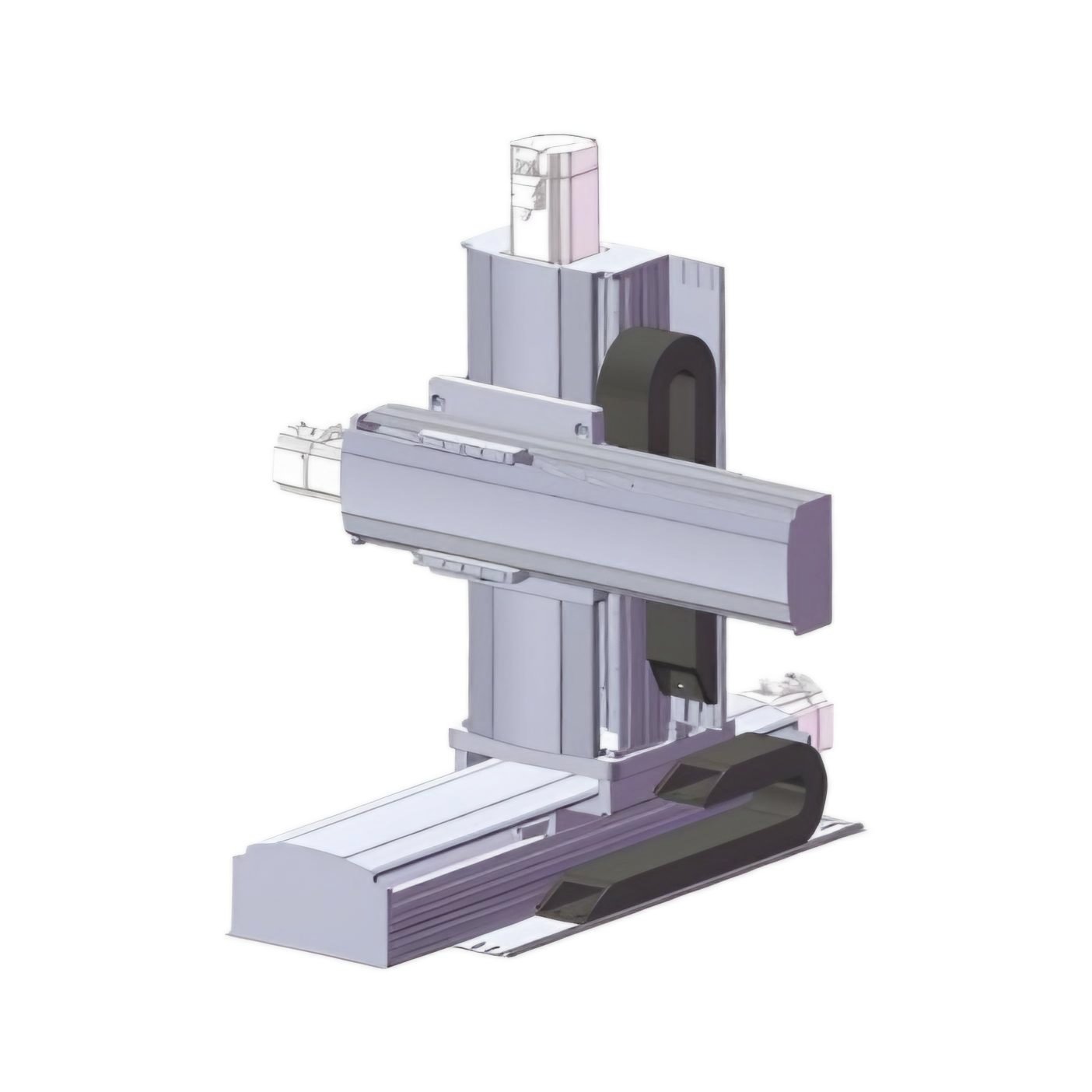

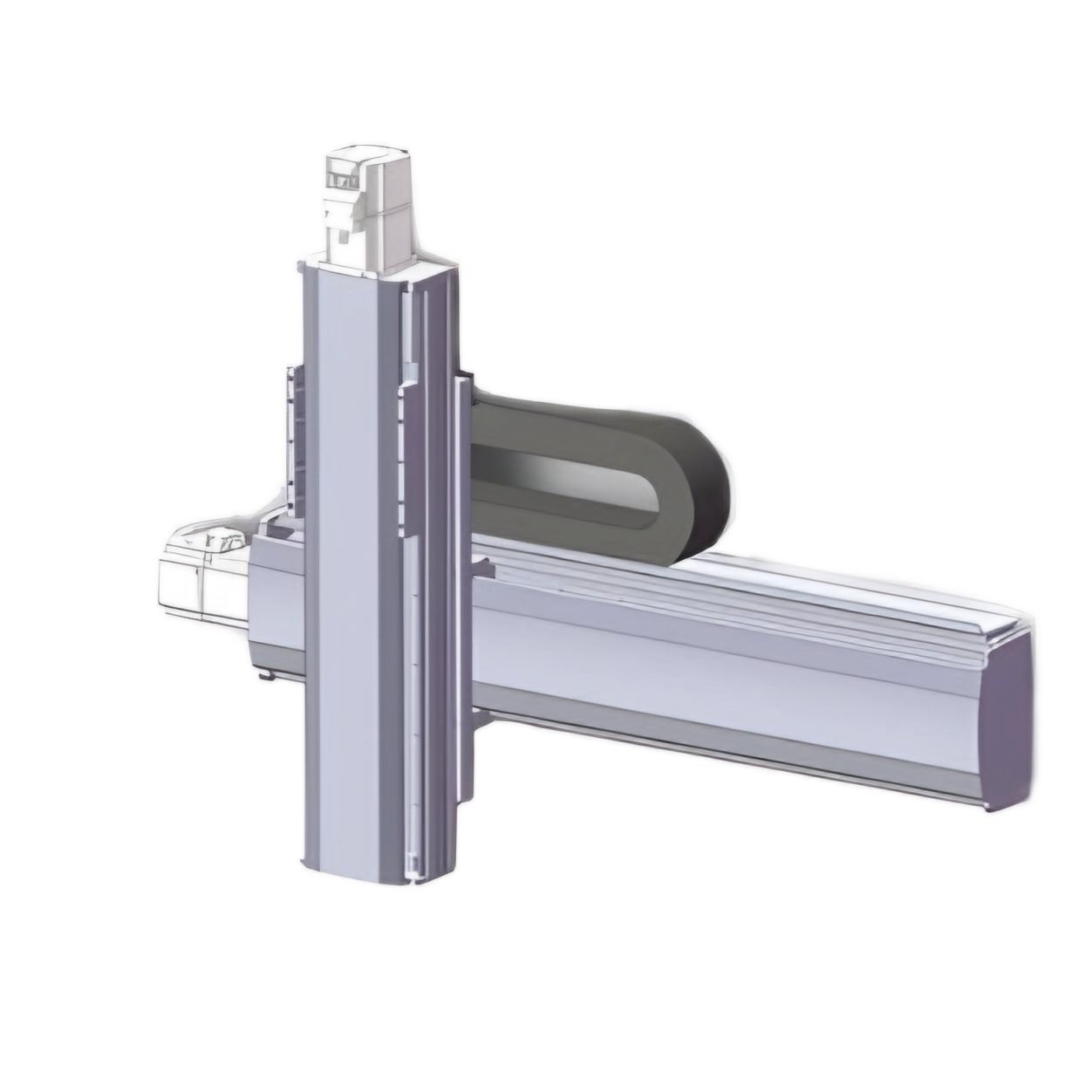

Tri-Axis Gantry

- Enables movement in three dimensions, perfect for complex tasks.

- Applications: Robotics advanced manufacturing, large-scale 3D printing.

Custom Gantry Solutions

- Tailored to meet specific requirements that standard models cannot fulfil.

- Applications: Unique industrial processes specialized manufacturing, custom automation projects.

Key Features

- High Precision: Engineered for accuracy and repeatability.

- Robust Construction: Built with durable materials for long-term reliability.

- Customizable: Adaptable to various sizes, weights, and operational needs.

- Easy Integration: Compatible with existing systems and infrastructure.

Benefits

- Increased Productivity: Streamline operations and reduce manual labor.

- Enhanced Accuracy: Minimize errors with precise control.

- Flexibility: Easily adaptable to different tasks and applications.

- Cost Efficiency: Reduce operational costs with automated solutions.

STANDARD SPECIFICATIONS

| Travel | 4 MTR | 8 MTR | 12 MTR |

|---|---|---|---|

| Load Carrying Capacity | 0 – 2000 KG | ||

| Structure | Double Column Type | Multi Column Type | |

| Configuration | LM RAIL – BLOCK + RACK AND PINION | ||

| Lubrication | Motorised Lubrication System | ||

| Drag Chain | IGUS / CKS MAKE | ||

| Surface Finish | BLASTING + MASKING +PRIMER + PUTTY + PU PAINT | ||

| Application | Welding | Pick and Place | |